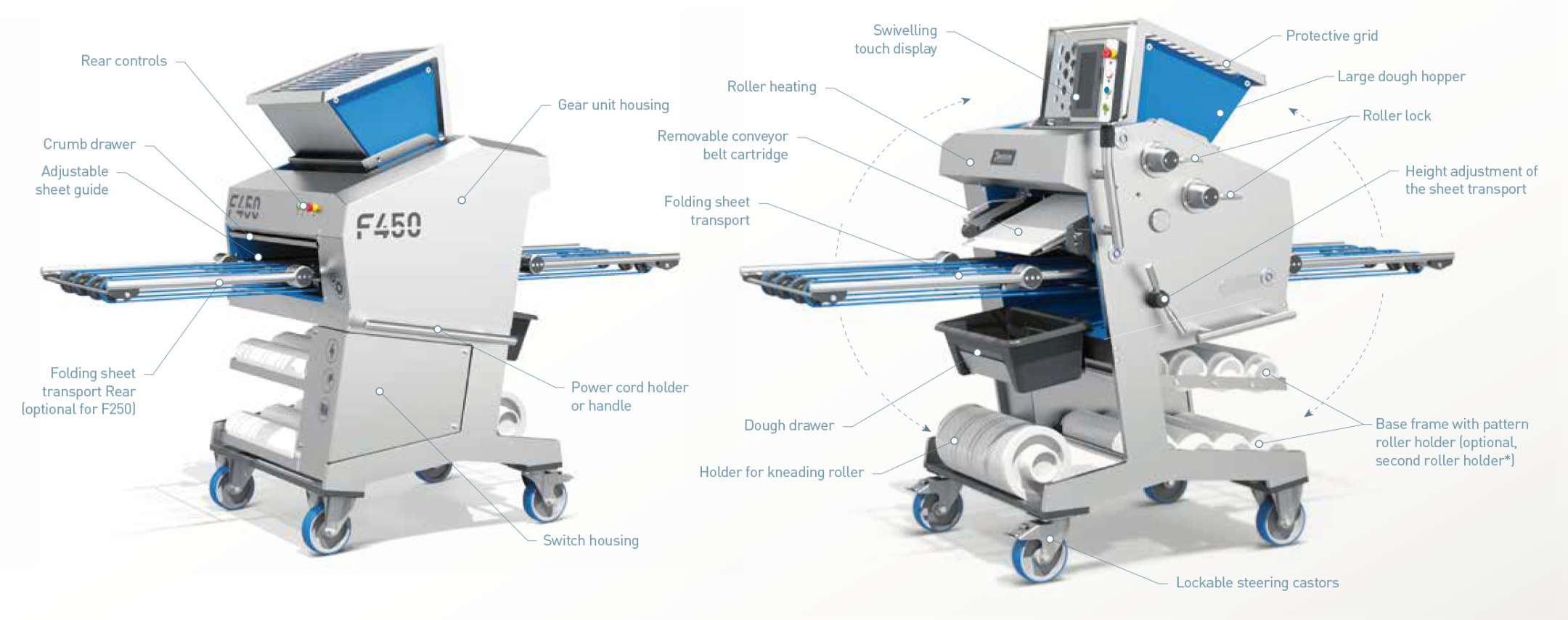

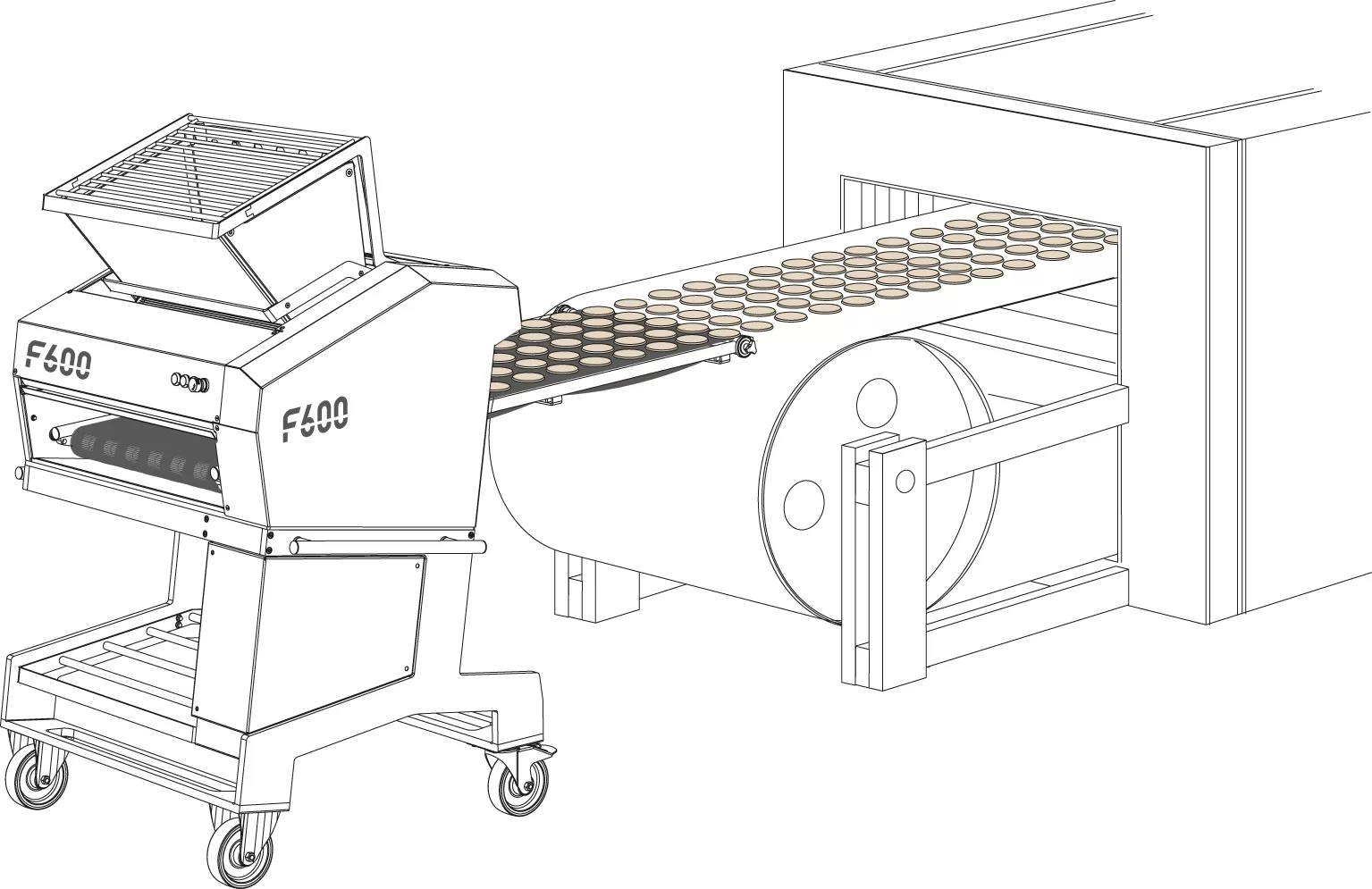

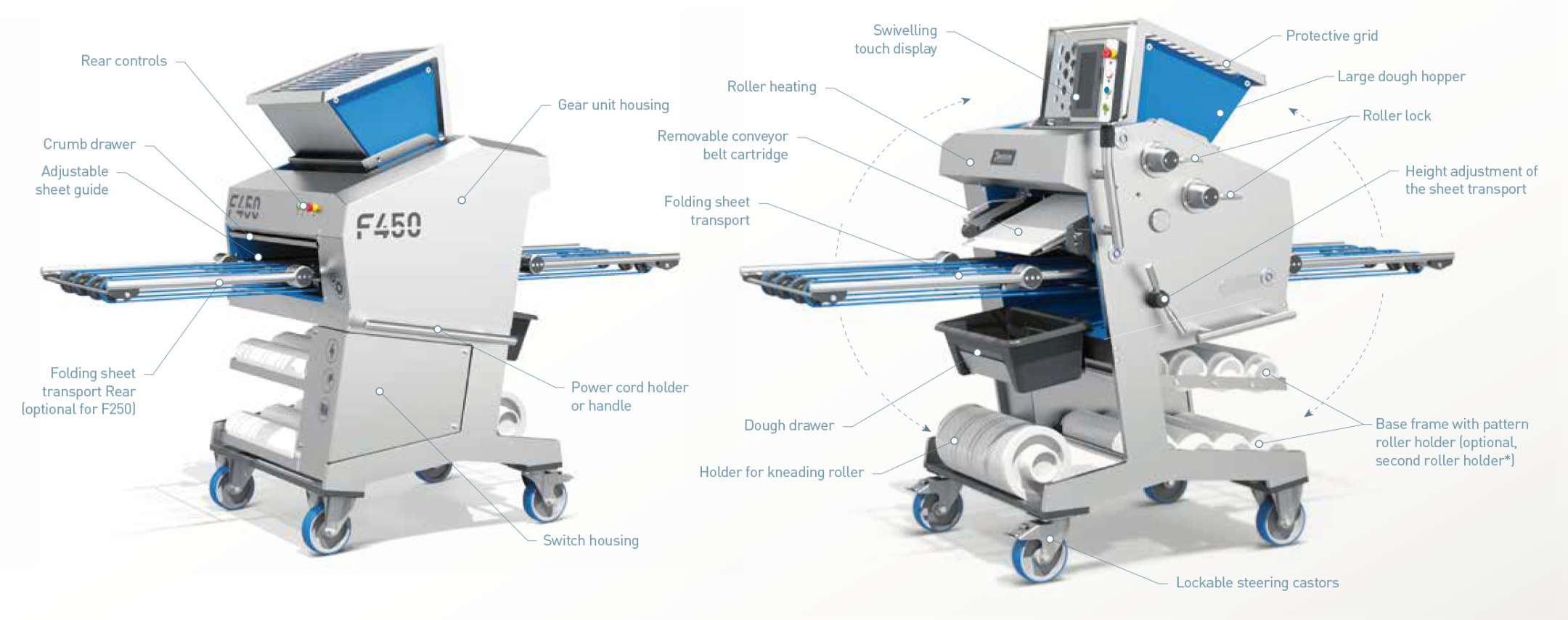

The Janssen F-Series Rotary Cookie Machine offers the following standard features:

✓ Hopper Feeding System

Dough is easily loaded into a large hopper where it can be processed into the machine’s rollers. This hopper also feature protective grid-style cover.

✓ High Production

Measured in pounds of dough processed/hour, this machine has a high processing capacity with reduced manual labor.

✓ Easy Cleaning

Machine has been designed with sanitation in mind and features a sleek stainless steel design, with removeable and wipe-down components. This includes:

- Use of FDA approved, food-safe materials

- Dough drawer for collecting scrap dough

- Removable conveyor belt cartridge for easy cleaning. This cartridge is responsible for depositing product directly onto the sheet pan.

- Crumb drawer for capturing dough particulates during the depositing process. This ensures the production floor remains clean throughout the depositing process.

✓ Compact Mobile Design

Innovative compact design that features:

- Folding input and output conveyor belts

- Base frame with roller holders

- Locking steering casters

✓ Safe Operation

A variety of safety features are included:

- Completely enclosed electrical components

- Completely enclosed dough processing

- Transport handle that also provides power cord storage (to prevent tripping when not in use)

- Supplemental rear controls that includes an additional emergency stop for enhanced safety.

- Roller locks to ensure that depositing rollers remain firmly in-place during operation.

✓ Brush Cleaning Kit

Keep all your machine looking brand new with an included brush cleaning kit. This includes a machine mounted brush holder, ensuring your kit remains in one easy to access place.

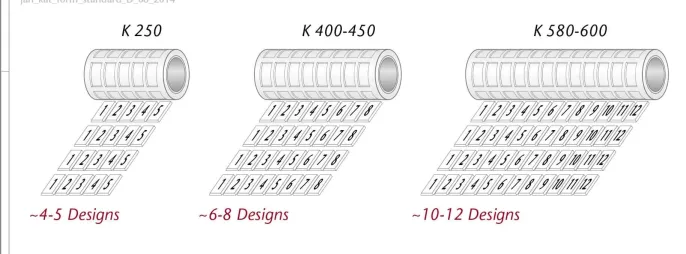

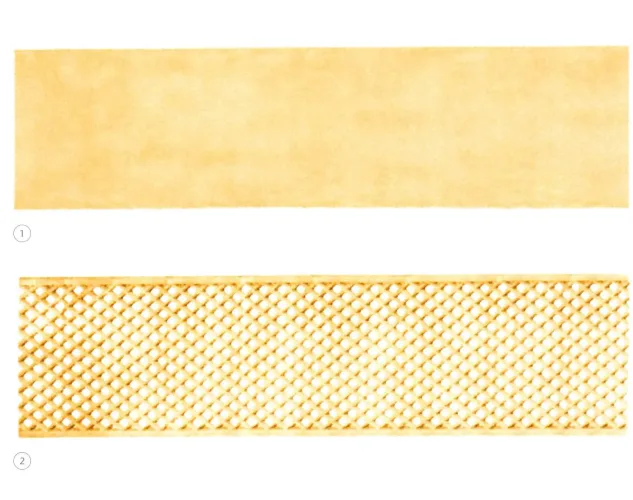

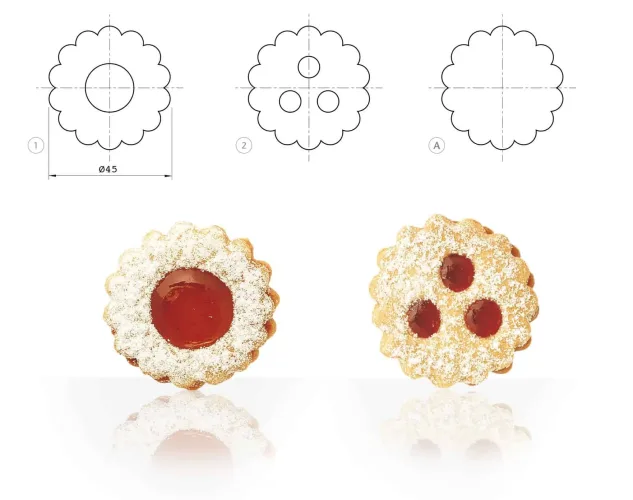

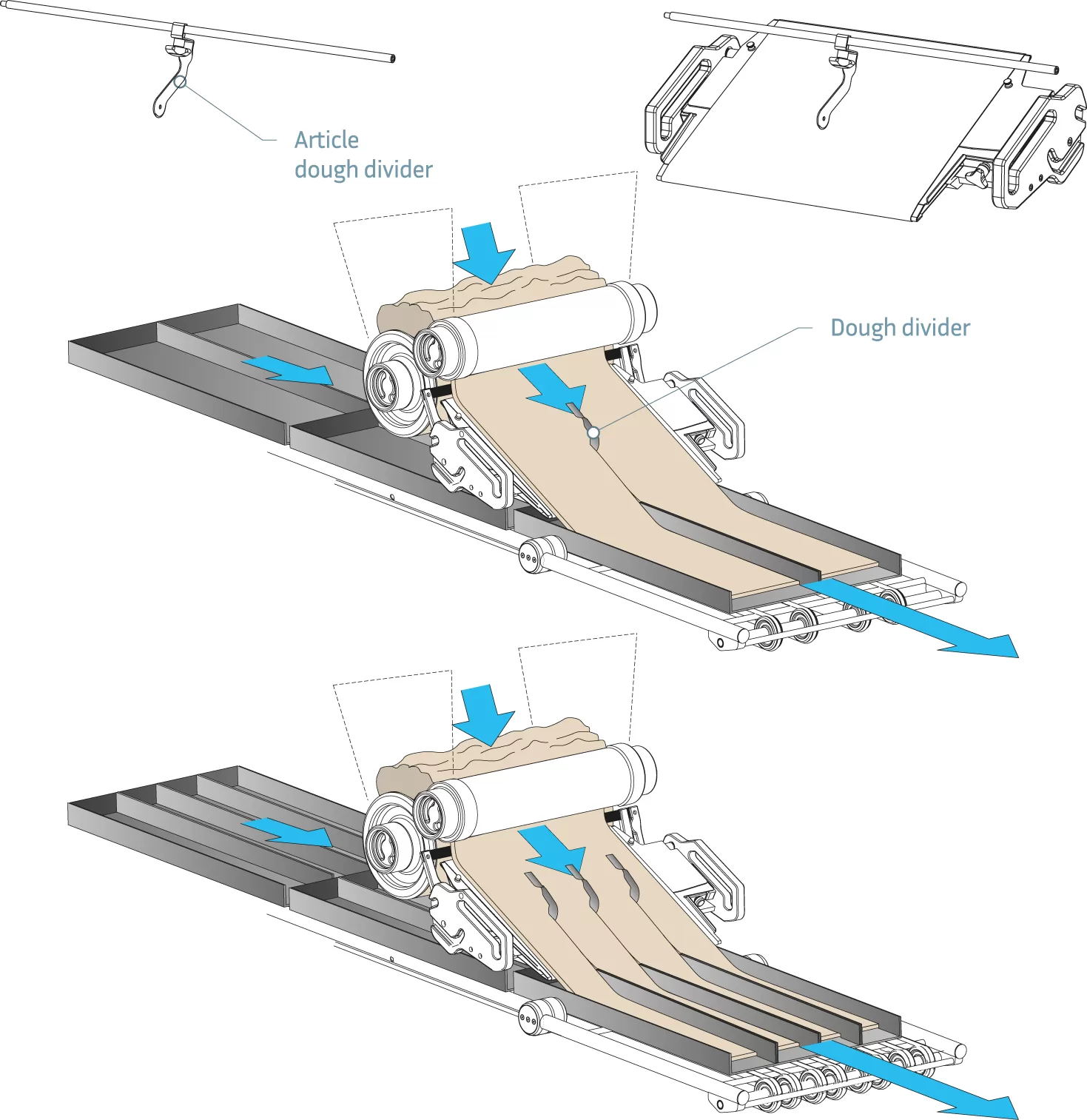

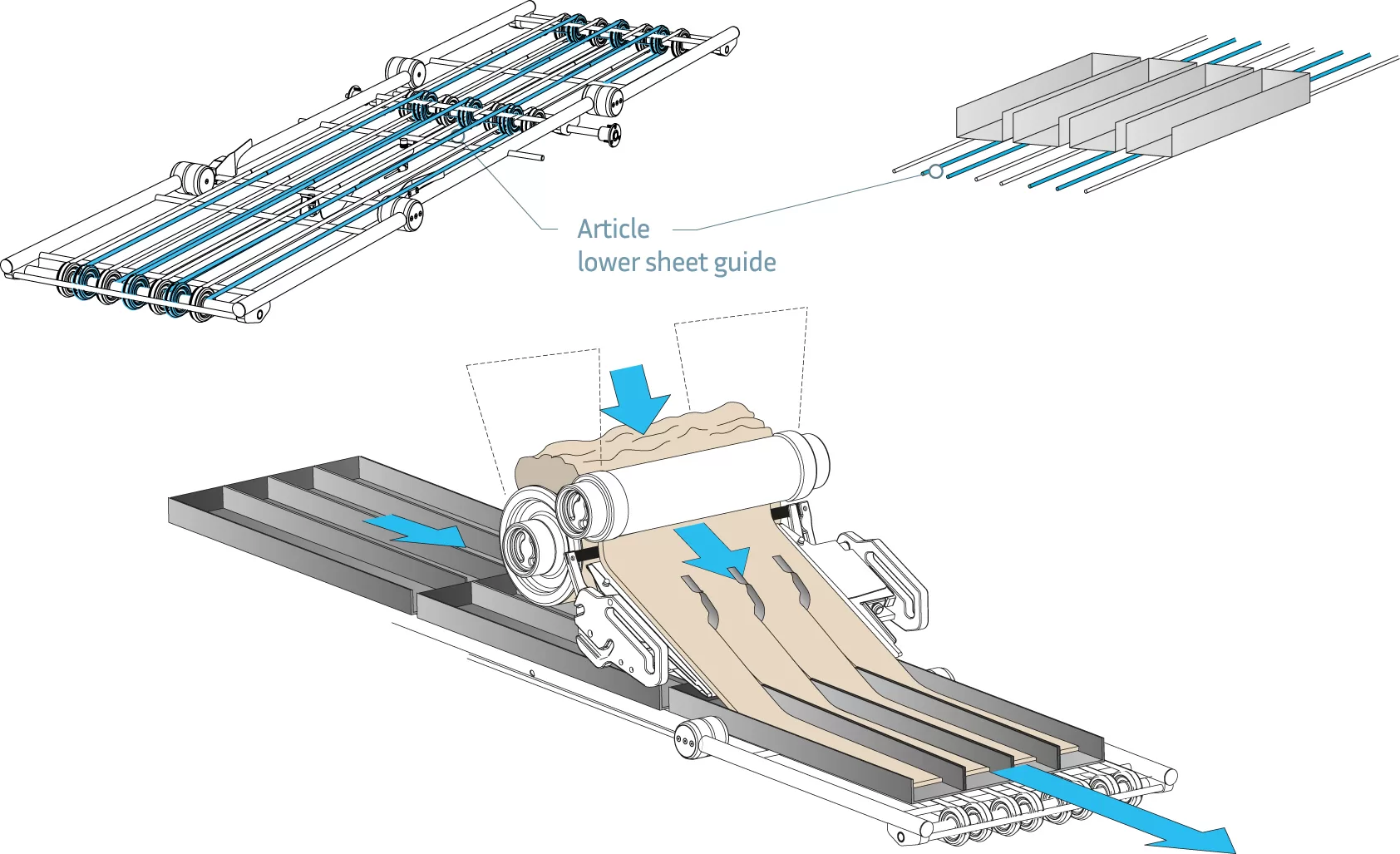

✓ Customizable Dies/Drums

Customizable, removeable rollers are available to create unique deposits.

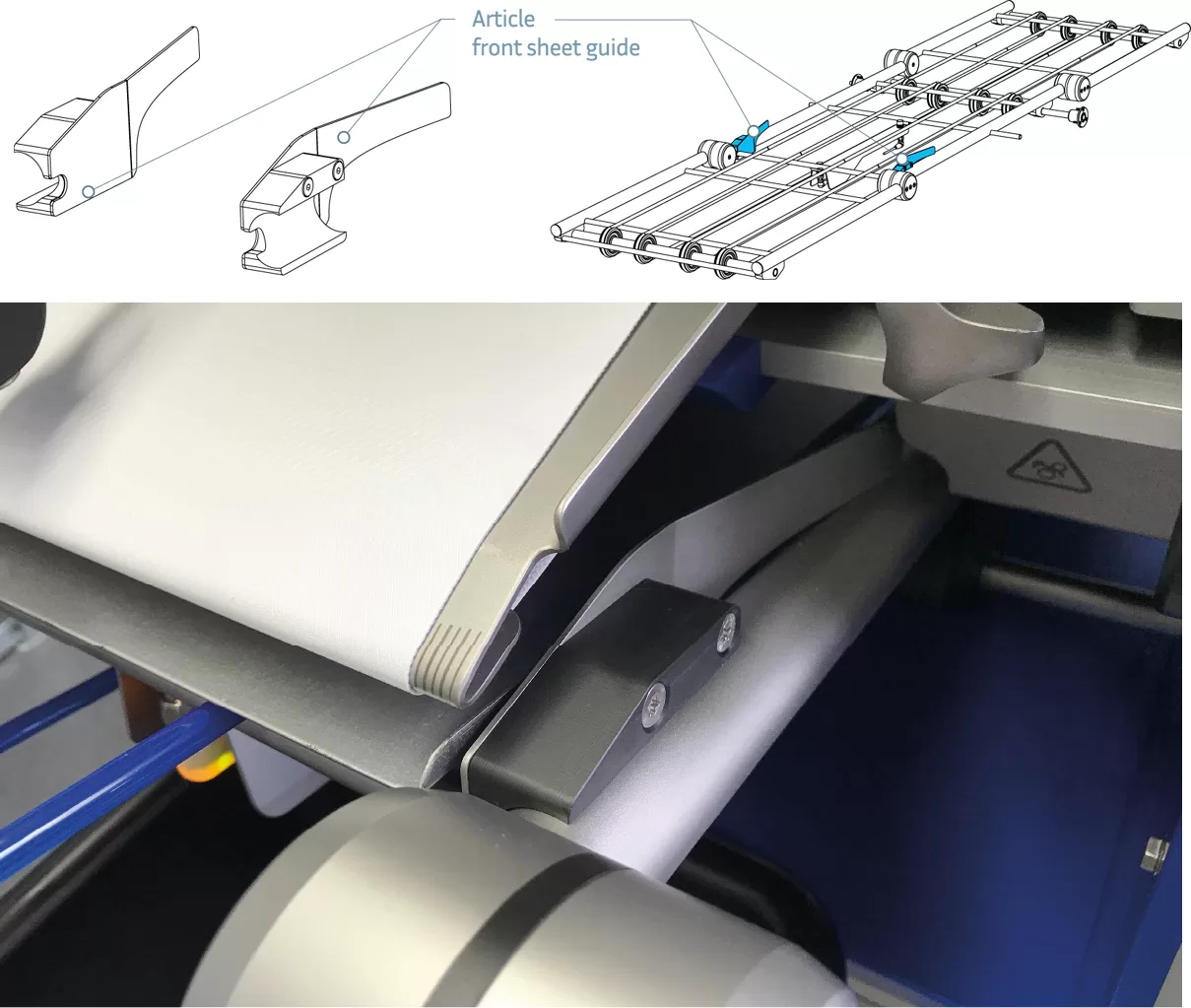

✓ Deposit Ledge

The deposit ledge facilitates depositing onto sheet pans with a raised edge/lip. This ledge serves as a bridge between the conveyor cartridge and sheet pan.

✓ Compact Control System

The standard compact control panel features a streamlined, button based design that provides simple and intuitive controls over the machine’s operation. Available parameters and features include:

- Permanent and automatic mode

- Constant overall speed (approx. 4m/13 ft. per minute)

- Adjustable pan/sheet/tray travel speed, that includes the ability to adjust the spacing of deposits onto the baking tray.

- Ability to control the heating of the forming rollers

- Swiveling design for enhanced ergonomics and user-friendly operation.

✓ Advanced Depositing Controls

Advanced depositing controls that streamline the production process and further customize the machines operations to each unique product you produce. Features and parameters include:

- Ability to adjust the level of heat applied to the depositing rollers for easier dough manipulation. This is extremely useful when attempting to process stiffer dough types.

- Adjustable sheet conveyor height to help reduce flight and ensure more accurate product placement.